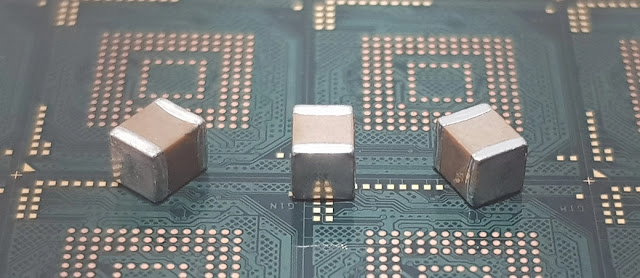

MLCC for 5G base stations has been developed by Samsung Electro-Mechanics.

On November 23, Samsung Electro-Mechanics announced the development of a high-capacity, high-voltage MLCC for 5G communications base stations. Samsung Electro-Mechanics’ new MLCC has a size of 3,225 (3.2mm wide, 2.5mm high), a high capacitance of 10uF (microfarad), and a high rated voltage of 100 V (higher voltage than the equipment can handle without being destroyed by the voltage) (volts).

Therefore, MLCCs mounted on 5G communication base stations must be a large capacity to minimize component mounting area and provide stable power. In addition, high voltage products are required due to the characteristics of the base station which use high operating voltages to reduce power loss and the products must also be highly reliable to operate normally in the face of environmental changes such as temperature. and humidity. The MLCC developed by Samsung ElectroMechanics this time reached the high capacitance of 10uF to provide fast and stable power to high-performance semiconductors. In addition, it can replace two to three low-capacity MLCCs, thereby reducing the component mounting area. In addition, the rated voltage of 100V can be safely applied to 5G communication base stations, and the increased reliability allows the MLCC to operate normally against environmental changes such as external shock and vibration, temperature and humidity. In particular, the new product benefits from the best tensile strength in the industry with a guarantee of 3mm.