Samsung Electronics, a leading global in advanced semiconductor technology, today announced HybridSubstrate Cube (H-Cube) technology, it’s own latest 2.5D semiconductor packaging option special for HPC, AI products, networking, and data centre requirements which necessitate large-scale packaging technology.

“In today’s environment, at which systems integration is becoming more important as well as surface supplies are becoming scarce, Samsung Foundry and Amkor Technology have successfully developed the H-Cube code to overcome this challenge,” stated “ JinYoung Kim, vice president of Amkor Technology’s Global RandD Center. “That invention lowers the entrance hurdle into the HPC/AI sector and illustrates a successful collaboration and partnership between both the foundry and the Companies outsource Semiconductor Running tests and Assembly (OSAT) firm.”

Structure and Functions of the H-Cube

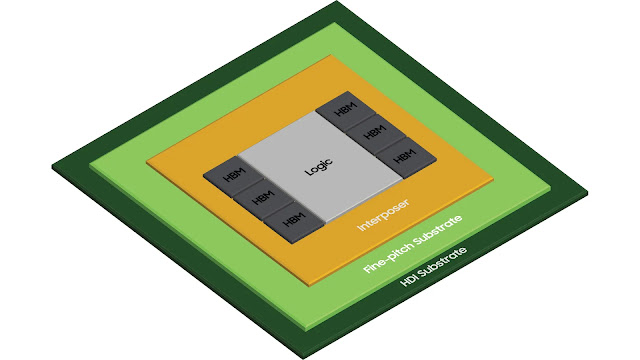

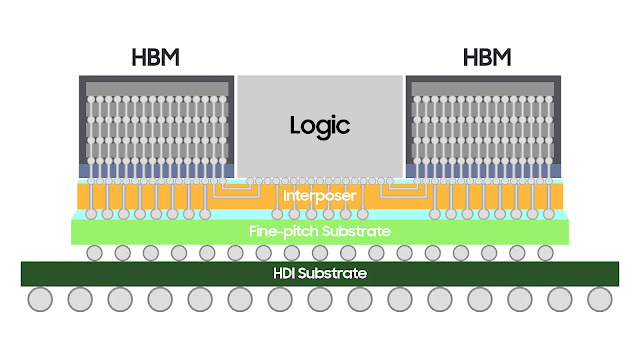

In a compact form factor, the 5D package allows users to install logic chips or high bandwidth memory (HBM) on top of a silicon supplements. Samsung’s H-Cube system involves a hybrid platform with a fine pitch platform capable of fine bump connections and a high density interconnection (HDI), allowing huge sizes to be implemented in a 2.5D packaging. Large-area packaging is becoming more significant when the quantity & size of chips put in a package grows or increases, as the consider in the HPC, AI, and network application market sectors have recently increased. It is necessary to have high-speed broadband communication. Fine pitch substrates are required for the attachment and connecting of silicon chips, including the interposer, but their costs rise significantly as the size grows.

|

| Concept of H-Cube™ Package Structure |

If six or more HBMs are combined, the challenge of creating the huge substrate grows quickly, lowering efficiency. Samsung resolved the challenge by using a hybrid substrate structure that combines easy-to-process HDI substrates with a high-end fine-pitch platform over a large expanse. Due to a 35 percent reduction in solder ball pitch, that electrically links the chip and platform, the size of the fine pitched platform may be reduced, while an HDI substrate (PCB module) can be added beneath the fine pitch substrate for secure interaction with the board system. Furthermore, in order to increase the H-Cube solution’s dependability, Samsung’s unique power and signal integrity analysis technology has been used to deliver steady power while reducing signal loss or distortion while stacking numerous logical and HBM chips.